Light Emitting Diode is a light-emitting device known for its power saving, durability, and safety. In recent years, rapid development has made it an essential part of our lives.

Did you know that there are several types of LED chips?

Today, Auxgrow will provide you with an understanding of different types of LED chips and their distinctions, assisting you in exploring your options, considering your requirements, and making informed decisions.

Different Types of LED Chips

LED, short for light-emitting diode, is a type of semiconductor device that emits light when an electric current passes through it.

It offers several advantages over traditional incandescent and energy-saving bulbs, which have made it increasingly popular and widely used.

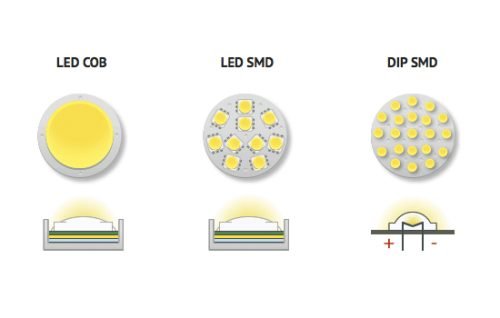

LEDs have developed into various types to cater to different requirements. Common types of LEDs include DIP LED, SMD LED, and COB LED.

However, it’s important to note that the variety of LED types extends well beyond these three examples.

DIP LED Meaning

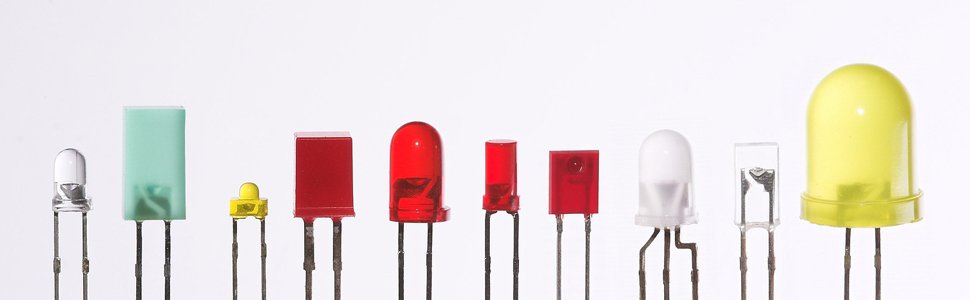

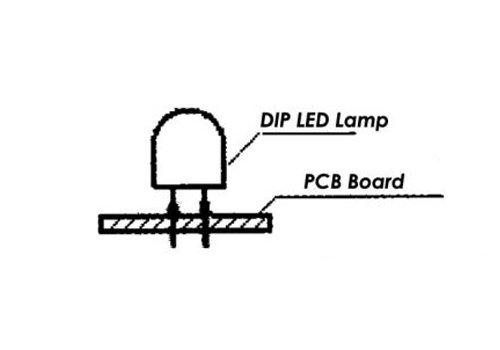

Let’s start with the first type of LED called the Direct Inline Package Light-Emitting Diode, or DIP LED for short.

Most people are familiar with and likely envision these types of LED chips when they think of LEDs.

DIP LED clips have been around for over 50 years since their invention in 1962. However, they have not been phased out and continue to be used today.

DIP LEDs are characterized by their low voltage, low heat generation, and high safety standards.

What is SMD LED Chip?

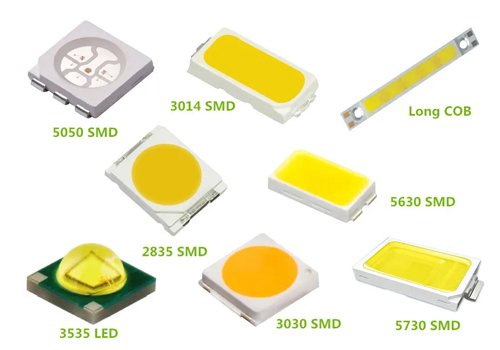

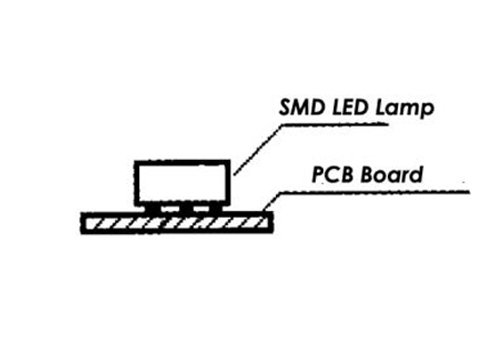

The second type is the Surface Mounted Device Light-Emitting Diode, commonly known as the SMD LED.

Clip LED SMD is characterized by its small size and low cost. Compared to DIP LEDs, it has a smaller form factor and relatively higher luminous efficiency.

What is COB LED Chip?

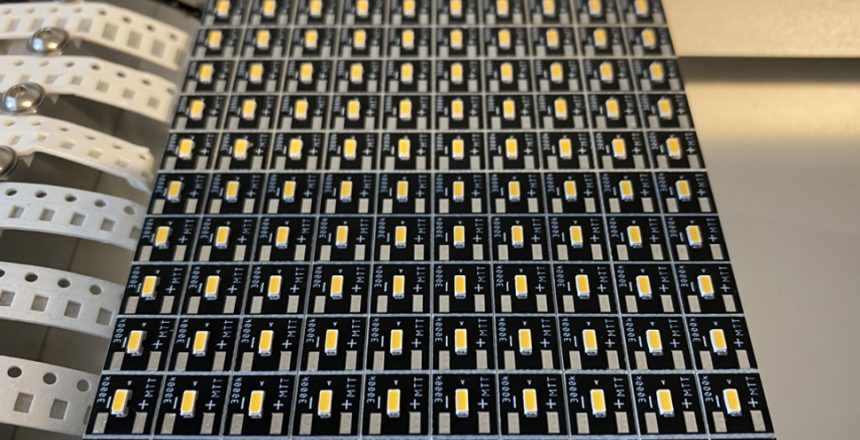

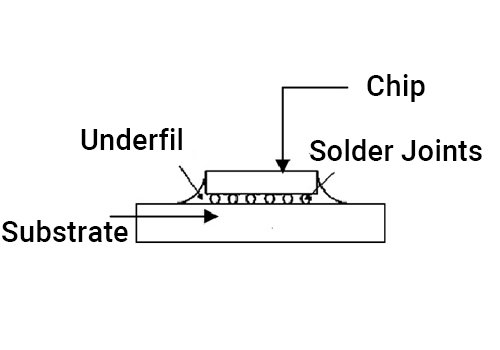

COB LED stands for Chip-on-Board Light-Emitting Diode, which utilizes a packaging technology where the LED chips are directly mounted onto a circuit board with high thermal conductivity.

As the name implies, a clip LED COB consists of multiple LED chips integrated into a single package. Its key features include high stability, efficient heat dissipation, and uniform light distribution.

How do You Identify LED Chips?

Now that you’re familiar with the different types of LED chips, it’s time to embark on an exciting journey of understanding.

Does identifying LED chips seem like a daunting task to you? Don’t worry! We are here to provide you with practical knowledge and convenient techniques to help you confidently distinguish between LED chip types.

Let’s dive in and illuminate your path to mastering LED chip identification.

Shape of Chip LED

It’s easy to tell apart these three kinds of LED chips just by looking at their physical appearance.

DIP LEDs come in various shapes such as round, square, or irregular. The diameter sizes typically range from 3mm, 5mm, and 10mm.

Chip on board LED can have a round, square, or strip shape, and their dimensions can be customized based on specific application requirements. Its size tends to increase with higher power ratings.

SMD LEDs primarily have a square-shaped surface mount package, with different sizes such as 2835 LED chips, 3825 LED chips, 5050 LED chips, 5730 LED chips, and so on.

And what is the difference between them?

In fact, we can divide these model numbers into two parts. One part corresponds to the length, while the other part represents the width of the LED chip.

On the market, there is another type of SMD chip known as high power LED chip. These LEDs are slightly larger in size compared to regular SMD LEDs. Some of them have a semi-circular lens on top, which is why they are also referred to as LED light beads or LED modules.

Welding Comparison

For LEDs like DIP chips, you need to pass their pins through the circuit board and solder them from the bottom. They can also be directly plugged into a breadboard for use.

On the other hand, SMD LED chips can be directly soldered onto the circuit board without the need to drill a hole like DIP LEDs.

COB LED chips are already attached to their own circuit board, so you only need to solder the power wires for them and they can be used directly.

The Polarity of Chip LED

The Polarity of COB

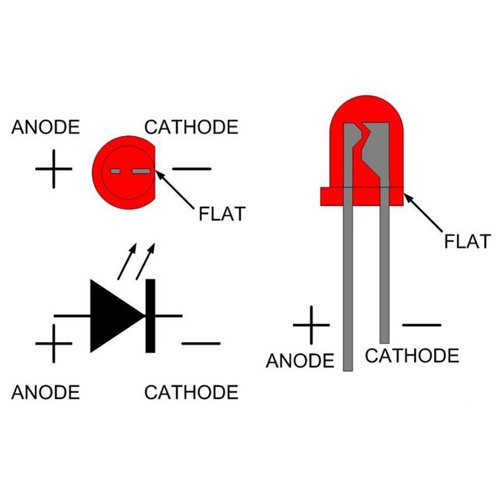

The longer pins are positive and the shorter pins are negative. Looking at the LED from the top also shows that one side is flat and the pin underneath it is negative.

The Polarity of DIP

In the case of COB LEDs, polarity is typically indicated directly on the circuit board, making it easy to discern.

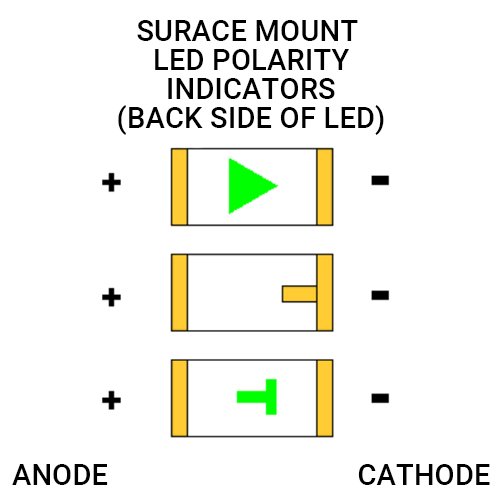

The Polarity of SMD

To determine the polarity of an SMD LED, we can observe its markings here. The pin with this marking is the negative (cathode) terminal.

There are also different ways to identify the polarity of the LED. If you have a multimeter, it will be easy for you to identify it.

Set the multimeter to the continuity or diode mode and touch the probes to the LED’s terminals. When the LED lights up, the terminal that the positive probe is connected to is the positive (anode) terminal.

It is essential to understand the specific functions of a multimeter. However, some multimeters are the opposite, like pointer multimeters. Based on the internal design, the polarity of the cathode probe will be positive when in the beeping gear.

Application of Chip LED

DIP LED Chips

Since DIP LED has limited lighting advantages, they are commonly used as indicator lights, in displays, or for low-power lighting tools.

COB LED Chips

COB LEDs are primarily used in lighting devices such as mobile phones, cameras, or spotlights. Additionally, they are preferred for applications requiring high brightness, such as streetlights or industrial lighting fixtures.

SMD LED Chips

SMD LEDs have a relatively wide range of applications. Their small size makes them convenient for installation in various devices, including LED bulbs, decorative light strips, LED grow lights, RGB color lights, and different other LED fixtures.

Actual Performance of Chip LED

To assess the actual performance of these LED chip types, we have provided specifications for DIP, SMD, and COB LEDs, all emitting cool white light.

- DIP LED: Operating voltage of 3.6-4 volts, draws 30 mA, and has an emission angle of 22 degrees.

- SMD LED: Operating voltage of 3-3.2 volts, current of 65 mA, and an emission angle of 120 degrees.

- High-efficiency SMD LED: Operating voltage of 3-3.2 volts, power consumption of 1 watt, and an emission angle of 130 degrees.

- COB LED: Operating voltage of 9.6-11 volts, power of 10 watts, and an emission angle of 120 degrees.

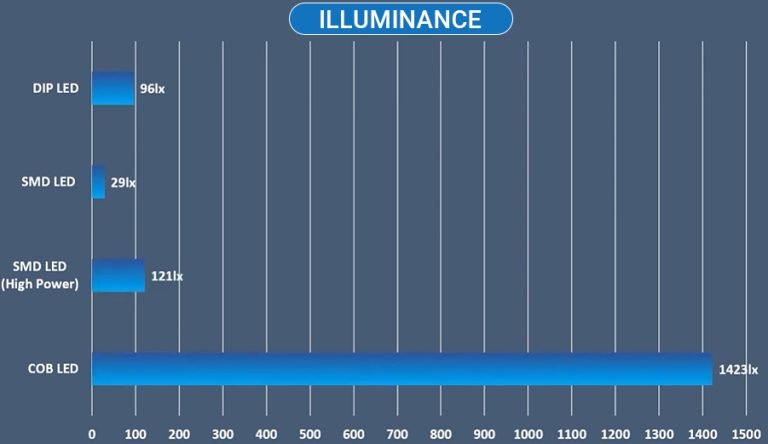

Next, let’s measure their actual brightness. With each LED type powered at its specified voltage, and placed 50 centimeters away from the LED, we obtained the following illuminance readings:

- DIP LED: Illuminance of 96 Lux

- SMD LED: Illuminance of 29 Lux

- High Power SMD LED: Illuminance of 121 Lux

- COB LED: Maximum illuminance of 1,423 Lux

If you wish to convert the illuminance readings to luminous flux, you can use the following formula:

Luminous Flux (in lumens) = Illuminance (in lux) × Area (in square meters)

To convert illuminance to luminous intensity, you need the LED’s luminous intensity and emission angle. Since the measurements provided are in lux (illuminance), we can convert them to luminous intensity by multiplying the illuminance by the measured distance.

Taking a DIP LED as an example, by multiplying the illuminance value of 96 lux by the square of the measured distance (0.5 meters), we get 24 cd. Assuming a beam angle (theta) of 22 degrees, the estimated luminous flux is approximately 2.77 lumens.

For SMD LED, with an illuminance of 29 lux and a beam angle of 120 degrees, the estimated luminous flux is approximately 22.78 lumens.

In the case of high-efficiency SMD LED, with an illuminance of 121 lux and a beam angle of 130 degrees, the estimated luminous flux is approximately 109.75 lumens.

For COB LED, with an illuminance of 1,423 lux and a beam angle of 120 degrees, the estimated luminous flux is approximately 1,117.62 lumens.

What is the Brightest LED Chip?

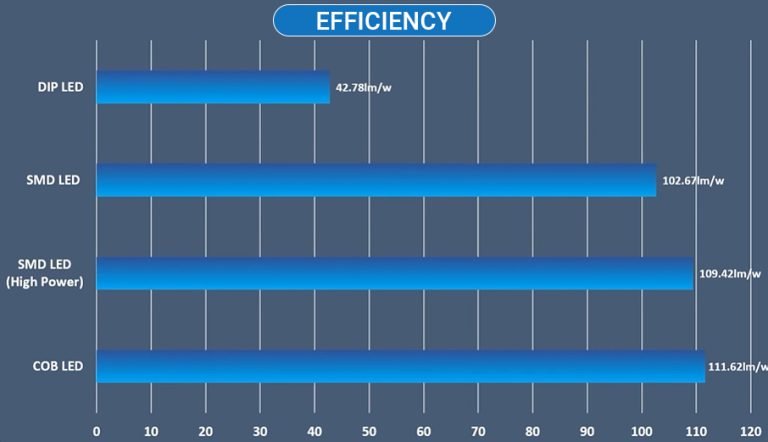

Once we have obtained sufficient luminosity, we can compare the light-emitting efficiency of different LED models.

In other words, we want to determine which LED can provide higher output under the same power consumption. By using the following formula, we can calculate the data:

- DIP LED: Approximately 42.78 lm/W

- SMD LED: Approximately 102.67 lm/W

- High-power SMD LED: Approximately 109.42 lm/W

- COB LED: Approximately 111.62 lm/W

From this analysis, it’s evident that COB LEDs have higher efficiency compared to high-power SMD, regular SMD, and DIP LED chips. However, in practical situations, there are other factors to consider.

LEDs cannot convert all electrical energy into light energy. The remaining electrical energy is converted into heat energy, which can impact the performance of the LED when the temperature rises.

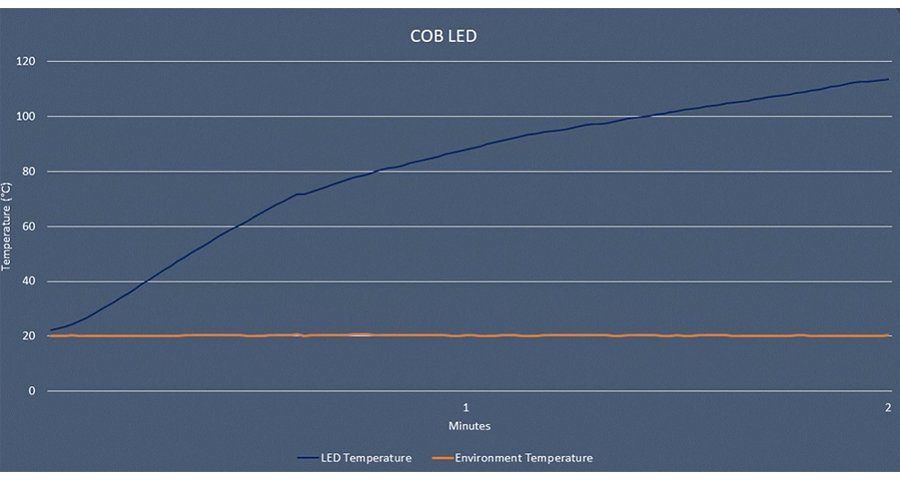

Now, we need to measure the variations in illuminance and temperature of the LED during normal operation.

For this test, I will attach a thermocouple to the LED without affecting the illuminance, and observe the temperature changes of the LED over a brief period of 10 minutes.

DIP LED Clip

In the first 3 minutes, the temperature of the DIP LED increases from 20.1 degrees Celsius to 28.2 degrees Celsius.

However, in the subsequent 7 minutes, the LED’s temperature remains relatively stable, ranging between 27 and 28 degrees Celsius. Throughout this process, the illuminance of the DIP LED consistently stays at 96 lux.

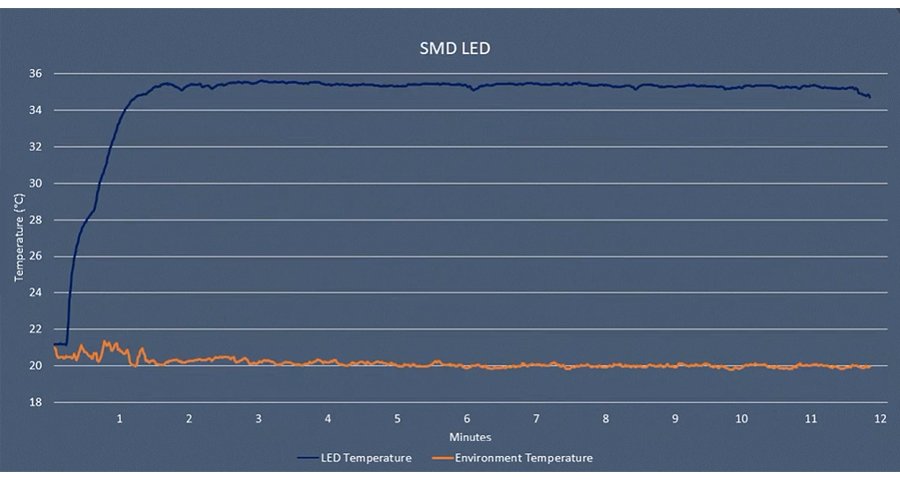

SMD LED Clip

The temperature of the SMD LED rises from 21.1 degrees Celsius to 35.4 degrees Celsius, which takes a total of two minutes.

Subsequently, the temperature remains steady between 35.2 and 35.6 degrees Celsius. The illuminance, however, is not affected by the temperature and remains constant at 29 lux.

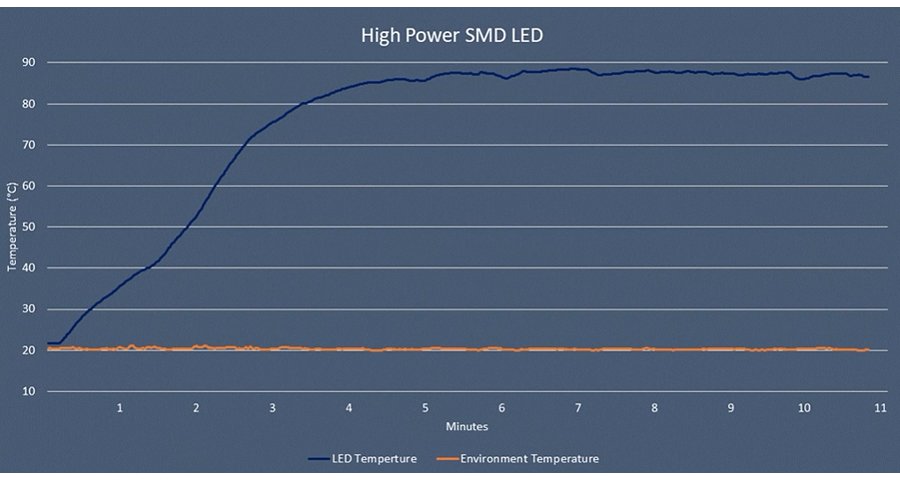

High Power SMD LED Clip

After powering on, the temperature of the high-power SMD LED continuously increases until it starts to slowly decrease after 4 minutes. The maximum temperature that the high-power SMD LED can reach is 88.94 degrees Celsius.

During the process of temperature rise, the illuminance drops from the initial 121 lux to 93 lux after 10 minutes.

COB LED Clip

In the testing of COB LEDs, it is essential to use a heat sink as a prerequisite. To prevent any damage, it has been decided to shorten the testing time to 2 minutes without a heat sink.

Upon powering on, the temperature of the COB rises at a rate of 1 to 2 degrees Celsius per second. After just one minute, the measured temperature reaches 87.9 degrees Celsius. By the second minute, the temperature has already reached 113.5 degrees Celsius.

However, the illuminance also drops from 1,423 lux to 917 lux under these conditions, significantly impacting their efficiency.

This observation demonstrates the heating issue that high-power LEDs face when operated without proper heat dissipation measures, such as a heat sink.

Warm Tips

If proper heat dissipation is not achieved, the performance of LED can be affected by the temperature it emits.

At Auxgrow, our LED grow lights are designed with excellent heat dissipation capabilities. Our goal is to ensure that the LED plant lights operate smoothly while providing users with a guarantee of safety.

LEDs commonly utilize aluminum circuit boards, also known as aluminum PCBs, which have superior thermal conductivity. This feature greatly aids in the heat dissipation of LEDs.

What is the Best LED Light Chip?

Regardless of the type of LED clip, each has its own advantages and disadvantages. It’s difficult to claim that one chip is definitively superior to others.

The best LED chip is the one that suits your specific needs and requirements. Explore your options, consider your requirements, and make an informed decision.

Choosing the correct LED chip is crucial for your specific indoor plant lighting needs. Auxgrow provides the best LED lighting solutions for your plants.

Auxgrow specializes in offering a wide range of high-quality LED plant lights and light chips to meet the unique requirements of indoor gardening.

Don’t miss out on the opportunity to provide optimal lighting for your green friends. Contact Auxgrow Today to learn how our LED grow lights can transform your indoor gardening experience.

Jayes

As a Digital Marketing Manager at AUXGROW, Jayes combines a passion for hydroponic systems and expertise in LED grow lights. With hands-on experience and a deep understanding, Jayes guides you through the world of sustainable cultivation.